EFI-890H Advanced Flight Display

R. Fred Polak | Editor

Integrated flat panel displays offer significant improvement in situational awareness while reducing pilot workload, both of which are essential to supporting the unique tactical requirements of rotary-wing aircraft. The high-vibration environment in which rotorcraft operate presents the need for flight deck displays to be rugged and high utility, yet provide intuitive visual cues for optimal situational awareness. Universal Avionics’ EFI-890H flight deck display has been qualified to the rigorous vibration profile testing of RTCA/DO-160F environmental standards for maximum performance during mission operations. Offering a high-resolution display of a synthetic vision system, collective cue display, night vision goggle compatible and designed for IFR flight, it truly is a system tailored to the tactical needs of helicopter operators. The system is optimally sized, featuring a lightweight, compact housing while offering an 8.9-inch diagonal active-matrix LCD display.

This high-resolution, high-contrast display provides superior readability throughout a full range of ambient lighting conditions including bright sunlight and dim nighttime environments. Extremely wide horizontal and vertical viewing angles are also accommodated.

System Purpose

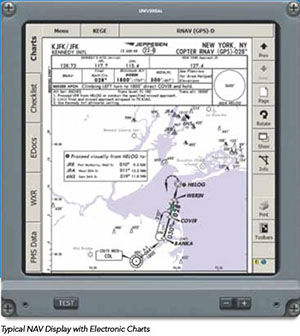

The EFI-890H displays can be installed as a multifunction display (MFD) only, primary flight display (PFD) only or combined as a complete system. The wide variety of interfaces and integrations supported makes it fit a wide range of helicopter applications. As an MFD, the display supports navigation maps, radar control and display, external camera/enhanced vision system (EVS) video, helicopter terrain awareness system (HTAWS), synthetic vision and external mission computer inputs. As a primary flight display system, the displays are fully certified for IFR with DO-178B Level A software. All displays are identical and interchangeable with harness-mounted configuration modules determining the display functions. The system currently meets environmental standards for 13 helicopter profiles (platforms). The EFI-890H can support anywhere from one to five display configurations, depending on the requirements of the operator.

Mission Performance for IFR Conditions

The EFI-890H supports an array of information and display capabilities for helicopter operators. To complement the display of primary flight data, a collective cue flight guidance display provides for optimal collective control when in “4-D” (four-axis) coupled autopilot mode, to aid in maintaining the desired flight path. Visual guidance on the PFD is presented in two configurable formats to meet operator preference, the “dual cue” cross-pointer or “single cue” V-bar overlay. The EFI-890H offers an advanced, large-format instrument suite that interfaces with many existing aircraft/flight deck systems.

Sensor Packages

There is no particular sensor package that is required by the operator. The system will interface with both analog and digital sensors and currently has the following integration capabilities:

• More than 17 types of attitude/heading sensors

• More than 14 types of air data sensors

• More than six known radio altimeters

• More than 13 different weather radar systems

• More than 10 different flight director/autopilot systems (including ASCB version A)

• More than five traffic collision and avoidance systems (TCAS)

• Supports numerous analog and digital radio systems

Installation

MFD-890R displays have been installed on field approvals. Integrations with PFD have been installed on non FAA certified programs. Several STC proposals are pending, including S-76, S-61, Blackhawk and Super Puma. Inquiries are ongoing with regard to various Bell and Eurocopter models.

Universal works with its dealer network which is responsible for installation approvals. Universal Avionics does not hold the STCs in most cases. Installations are only accomplished through the Universal dealer network.

There are no special mechanical or electrical considerations to take into account on an installation beyond normal practices and all certification requirements. The EFI-890H supports ARINC 429, RS-422, Manchester and CSDB data buses. Protocol converters can be used to support Mil 1553 applications.

The EFI-890H provides built-in-test (BIT)and also provides integral fault logging. It also provides a built-in monitor function for digital and discrete inputs for testing/troubleshooting. No special test equipment is typically required, but a PC can be used to download fault logs for analysis.

LRU programming is accomplished through configuration modules in the system, and are programmed using the bezel buttons on the display with menus displayed to the installer. Using a PC, configuration data can be saved for offline use and transferred to modules in another installation.

Standard and Optional LRUs

The number of standard and optional LRUs varies with the package the operator has purchased. As noted above, MFD only, PFD only and various combinations of two, three, four or five displays are supported. Each EFI-890H display is a “system,” including analog and digital I/O processing, computation, graphics generation and the display itself. Each display typically requires one display control panel and a course/heading control panel is installed with a PFD controller for integrations including a PFD. Optionally, a reference set panel is installed when altitude alerting or altitude pre-select for a flight guidance system is needed. If digital and discrete I/O exceeds what is available in the displays, a data concentrator unit (DCU) may be added to expand the I/O of the displays. Synthetic vision, electronic charting, HTAWS and mission computers are optional external peripheral devices.

Maintenance

As with all avionics systems, there are certain maintenance tasks to be performed and in the case of displays, there are some things to be avoided. The manufacturer’s aircraft maintenance manual is always the reference to be followed, but here is a short list with regard to the EFI-890H Display System.

Cleaning agents and materials: A very mild soap or dish washing detergent can be used, as can a 50/50 mix of vinegar and water. A 50/50 mix of isopropyl alcohol and water can also be used. The material used to wipe the front of the display should be a lint-free fabric that is non-abrasive and anti-static. Examples are tissue wiper, Kimberly-Clark Kaydry and EX-L Laboratory Wipers, to name a few.

Cleaning procedures: DO NOT USE COMPRESSED AIR TO CLEAN THE EFI-890H. DO NOT ALLOW FLUID TO MIGRATE TO THE INTERIOR OF THE UNIT.

(1) EFI-890H chassis

(a) Wipe with a clean, lint-free fabric moistened with soap, detergent or a mixture of vinegar and water.

(b) Wipe with a clean, lint-free fabric moistened with clear water.

(c) Dry with a clean, lint-free fabric.

(d) Let the case stand open (or with cover removed) until any remaining moisture evaporates before assembling the unit.

(2) EFI-890H display

(a) Wipe with a clean, lint-free fabric moistened with a 50/50 mixture of isopropyl alcohol and water.

(b) Dry with a clean, lint-free fabric.

Never use chemicals to clean the display that is not listed above, as this could damage the unit and void the warranty. The display also utilizes a high quality anti-reflective coating to reduce glare on the display in direct sunlight. Using cleaning agents and materials that are not approved can negatively affect the performance of this anti-glare filter.

Cooling and filters: External forced air cooling is not required; however, provisions must be made to ensure unrestricted air flow around the EFI-890H and a path for hot air to be exhausted from the instrument panel. Additional information is contained in the installation manual.

There are no filter elements that need to be checked, cleaned or replaced on any schedule.

Tests Done in the Field

The system power on self-test and continuous BIT ensures proper operation of the EFI-890H, and inputs are monitored with flags provided when sensor inputs fail. A test button on the bezel provides a lamp/color test screen and when on ground initiates a user activated BIT. This is not required for normal operations. Color calibration is done at the factory and is not required nor can it be done in the field. All of the systems LRUs are certified to be “on-condition,” so there is no requirement to have them tested at any particular time interval.

Handling of the Displays

Handle the displays with care. It’s recommended to cover the display with blue poly mask film prior to removal to protect the LCD. Details/availability of this material is listed in the installation manual. Once disconnected, the display connectors should be protected with connector cover plugs. All LRUs should be packaged with ESD shielding bags when handled/ packed for shipment. When installing, ensure mating connectors are fully engaged and locked before applying power.

Tips and Lessons Learned

Universal Avionics provides assistance with an installation from the early planning stages. The first typical step is to survey the aircraft/rotorcraft to determine compatibility or issues with existing equipment that will be retained and identify what components or equipment will be interfaced with the display system. Universal can provide a spreadsheet to collect this data and prevent unexpected surprises. The installer/integrator fills out the worksheet and sends it to Universal for review. They then identify compatibilities/incompatibilities and provide some suggestions for addressing any issues.

A block diagram is a good next step by the installer and this helps with later detailed design and training the customer. Universal provides a “port allocation” spreadsheet tool which allows the installer to identify how all I/O ports/pins on the system are planned to be utilized. This spreadsheet helps later with the configuration setup process. Universal’s customer support department can provide design reviews and assistance with the project. They maintain a file folder on their server with details for each specific project and have a vast collection of knowledge as a result. Customer/dealer installation specific data is, of course, kept confidential. Universal Avionics’ Customer Support department (with prior planning and coordination) can provide on-site assistance during the setup and check-out phase right through certification. Some suggestions:

• Do contact Universal early in the proposal process – its team is there to help.

• Do get accurate information on the rotorcraft.

• Do discuss/coordinate the project early with certification authorities. In the U.S., wherever possible, consider ODA/maximum delegation versus an FAA oversight project.

• Don’t make assumptions about interfaces/integrations not listed in Universal’s installation manual without consulting UASC.

• Do take advantage of Universal’s assistance with drawing, certification plan and test plan reviews.

• Don’t hesitate to contact Universal Customer Support with questions during any phase of the project.

There you have it, the EFI-890H advanced flight display, tailored to fit the tactical missions of helicopter operators. Featuring flexible integration capabilities and multiple support interfaces, the EFI-890H is the perfect fit for helicopter flight decks.