Gremlins Live in Helicopter Engines

There is an old saying in aviation that “power is speed and altitude is life.” The engines used in helicopters provide all the power for both speed and altitude. Without the engine(s), the gearbox doesn’t turn and the rotors don’t spin. Enough said.

With a few exceptions, the vast majority of helicopter engines are called turbine engines. Turbine engines come in two types. Those that produce thrust by expelling exhaust gases are called fanjet engines. Those that use the same exhaust gases to spin a drive shaft are called turboshaft engines. Helicopters use turboshaft engines.

The helicopter’s transmission reduces the turboshaft’s spinning from thousands of revolutions per minute (rpms) to hundreds of rpms. The helicopter’s rotors cannot work at thousands of rpms. This speed reduction also increases torque, giving the rotors more lifting ability. If we lose the engine(s), we lose our source of power and can no longer sustain flight.

This is the second article in a series of articles, (see the April/May issue of Helicopter Maintenance magazine for the first article), wherein we will talk to some the industry’s leading MROs on what they see coming in the door as engine problems, and some suggestions on how to minimize them — or at least to recognize a problem might be around the corner

For this article, we spoke to staff at Aeromaritime, a member of the ITP Group, to gather information that will help the users of RR-250 engines recognize some areas that can be harmful to the life of their RR-250 engines. This in no way means there are any problems with the engines, but rather that there are things to be aware of under normal wear and tear.

In their own words, “Aeromaritime started business in 1971 as an authorized distributor of the Rolls-Royce Model 250 Series gas turbine engine for the Middle East and Africa. Rolls-Royce instituted the conception of authorized maintenance centers (AMC), and Aeromaritime was designated as such. In 2010, Rolls-Royce changed their business model, adding authorized maintenance, repair and overhaul centers. Aeromaritime again was selected as one, and since then we have also added customers in Europe and North America. In sum, today we have grown to have a world wide customer base.

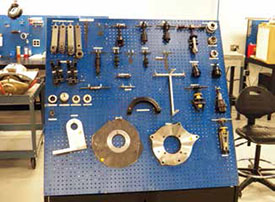

“We have a comprehensive repair, overhaul and test facility in Mesa, AZ, that handles the complete range of Rolls Royce Model 250 Series turboshaft and turboprop engines. This facility is fully approved by Rolls-Royce. Work performed at the Mesa facility constantly meets the highest quality standards and is backed by an extensive, comprehensive warranty policy. Aeromaritime America Inc. operates as a subsidiary of Industria de Turbo Propulsores S.A.”

Helicopter Maintenance magazine thanks Aeromaritime America’s Elisa Sobarzo, general manager; George Adams, regional sales manager; and Chuck Hagen, a talented maintenance professional, for their help with this article.

Flared Tube Installation

Flared tube installation can set up many issues if it is not done correctly. Tube wear, flare cracks, leaks and chaffing are the first items that come to mind. When installing inspected tubes, the best/correct method would be to install the b-nuts on both fittings by hand prior to using a wrench. If you cannot run down the b-nuts by hand, look to adjust the fittings if possible. Tubes should not have to be forced to run down the b-nuts, and b-nuts should not be used to pull the tubes down and into position. Allow the tube to find its running position by wiggling it. Then use a wrench and a backup wrench on the b-nut and fitting to properly torque the line.

This is an excerpt from the Rolls-Royce M250 10W2 Operation Manual:

WARNING: PROPER TIGHTENING OF ENGINE TUBING CONNECTIONS IS CRITICAL TO FLIGHT SAFETY. CORRECT TORQUE VALUES MUST BE USED AT ALL TIMES.

CAUTION: FAILURE OF ENGINE PNEUMATIC OR FUEL TUBES DUE TO FAULTY MAINTENANCE PRACTICES COULD CAUSE FLAMEOUT, POWER LOSS, OR OVERSPEED.

“Tube assemblies must fit and be aligned with the mating flare tube fittings to the degree that at both ends of the assembly; the flares shall be uniformly seated in a free state on the cones of the mating fittings. The fit shall be without distortion or stretching of the tube assembly and to the degree that the nuts can be fully engaged up to the final one-half turn with light finger pressure.”

CAUTION: THE PRACTICE OF TIGHTENING FITTING LOCK NUTS WITH TUBE ASSEMBLIES INSTALLED CAN RESULT IN DAMAGE TO THE TUBE WITH POSSIBLE FAILURE OF THE TUBE ASSEMBLY.

Seal Design Changes

The RR-250 engine line, as well as those of other manufacturers, has had four seal design changes in the last few years. Some of this is due to the manufacturers not being able to produce the seals they had in the past per Environmental Protection Agency (EPA) rules affecting their manufacturing process. Others were design improvements. Generally, leaking seals are going to be addressed by replacing the seal. Is that always the problem or are we missing the fix? Does the gear shaft the seal is running on have a rough seal runner area? Is the seal bore cracked? Seal leaks can be verified with a black light in most instances and aircraft oil will generally fluoresce when a black light is used without any additives. This can help determine the source of the leak.

Carbon Seals

Carbon seals should run leak free until the carbon face is worn away. Leaking for any other reason would be considered a premature failure. Strict following of the manufacturer’s instructions concerning the carbon face is very important.

Human Factors/FOD Complacency

FOD is generally caused by a lack of attention to detail. Leaving a cleaning rag on an engine deck when replacing panels and subsequently sucking it into the engine is avoidable, but it does happen. Forgotten tools, dropped hardware, etc., all become possible FOD and accident investigation findings. Another problem we see is leaving metal filings on a deck following the completion of a sheet metal repair or alteration. These filings can be ingested into the engine and lead to engine damage caused by FOD.

Consider this your guide to looking for and identifying engine gremlins in the Arizona sunshine, all from a company that knows what to look for and where to find it.

George Adams and Chuck Hagen | Contributing Authors