Night Vision Instrument Systems Maintenance Concept

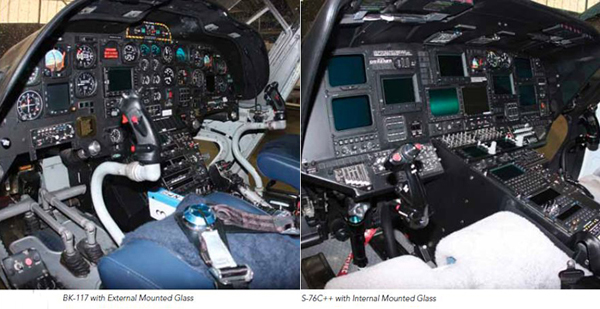

One of the most important safety features in flying helicopters at night or in reduced visibility, especially in single pilot-rated helicopters, is the use of Night Vision Goggles (NVG). There are several vendors offering Night Vision Instrument System (NVIS) Supplemental Type Certificate (STC) modifications. Some use external glass that is mounted directly to the instrument face or glass that is mounted internally under the face plate. Sometimes the lighting is modified by applying a special coating to the instrument’s bulbs or lamps. Options are getting more and more complicated and like all else, the cost is in the design.

The challenge for maintenance personnel to maintain the NVIS is in the options that are available. Each STC modification comes with Instructions for Continued Airworthiness (ICA). It is important that maintenance personnel become familiar with this document for the repair or replacement of parts within the NVIS. When performing maintenance, following the ICA will keep the NVIS up to its airworthiness standards. Below are two examples.

Mission readiness

Having worked with both types of installations, here are some lessons learned that will help to keep the NVIS and the helicopter mission ready.

Spare parts are extremely important and a huge expense. Ask the STC holder for a list of what they recommend for provisional stock. Once the list is received, go through it and make a decision on the items that can quickly and easily be changed in the field, per the allowed repair section of the ICA. Not everything the STC holder recommends will be cost effective or even realistic in nature, so make the choice based on past experience on frequency of failures or what can be easily damaged, from things like wear and tear, pilot’s helmets, replacement of instruments, etc. On aircraft with internal glass in high-end instruments, it’s probably going to be financially prohibitive to stock spares, so try and work with the vendor or the manufacturer to stock the high-dollar items.

Repair of these parts can be challenging also. Prior to deciding on a vendor to install the NVIS modification, it is a good idea to get answers to the following questions:

Will they support the equipment being modified in house or is it outsourced? Work with them and put your expectations on the table for turn-around parts.

Will the STC holder approve the components being modified through the part manufacturer? There are avionics manufacturers that will not support their product after it’s been modified by an STC. This will be a factor on how hard or long it will take to get parts repaired and back in service in a reasonable time.

Proper labelling

When changing out components, make sure to keep in mind the NVIS modifications. Depending on the STC, the instrument may appear to not have been modified, but in fact it has. Any vendor that has modified a part will label it as such with a modification label or stickers to let maintenance personnel know that the part has been modified. When in doubt, contact your STC holder.

Installation of the NVIS glass is very important. Follow the STC ICA instructions. If the ICA calls out specific parts or ways to install the glass, make sure the consumables called for are available. Most consumables are specific to the job and are called out for a reason. Don’t just glue glass on the instrument. It’s imperative to use only the recommended products.

It does not help if the pilots are unable to read the instruments. They may look OK in daylight, but in darkness they can become a problem. Even bulbs and lamps can have a coating of NVIS paint, so if these parts are changed, pay close attention to the part, because these are too small to mark as a modified part. Remember that only ICA-approved maintenance should be performed. Most bulbs are actually tested for their brightness under a controlled process through the STC holder’s certification process.

MELs

What is or is not listed in the Minimum Equipment List (MEL) will determine the helicopter’s availability for dispatch. Make sure that the MEL allows the helicopter to dispatch in the event of a discrepancy. The FAA has released a Master Minimum Equipment List (MMEL) Global Change (GC-166) policy letter #127. This GC is an approved addendum to all existing MMEL documents. Operators may seek use of the specific relief contained in the policy letter by revising their MEL.

Any future modification to the helicopter now becomes a new challenge and any upgrades could affect the NVIS installation. It’s a good idea to coordinate through the new STC holder and inform them that your aircraft has been modified with a NVIS. If this is not done, it can come back to haunt you and cause significant problems later on. Make sure the vendor doing a new installation has the modification reviewed by the original STC holder. The choice of vendor should not become an issue in the middle of the installation or affect any warranties. Many avionics components can be purchased directly from the vendor and are already NVIS ready.

In any case, the responsibility to assure the NVIS installation is not going to affect any previously installed STC is that of the operator or maintainer. Most STC holders are happy to be informed and will make any necessary changes to their STC.

Edward Jerin

Edward Jerin

ERA Helicopters

Aviation Maintenance Manager

Boston Med Flight

Hanscom Air Force Base

Robins Street hangar 1727

Bedford, MA 01730

Edward joined Era Med LLC in 2008 as the Aviation Maintenance Manager for its Boston Med Flight critical care transport service contract. It operates one S76 C++ and one BK117 C1 helicopter based at Hanscom Air Force Base in Bedford, MA. It also operates one BK-117 C1 helicopter out of Plymouth Municipal Airport in Carver, MA.