THE CARE AND FEEDING OF YOUR HELICOPTER’S PAINT JOB

Today’s helicopters are painted with polyurethane type paints. Whether it is DuPont, PPG or Sherwin Williams, the same basic rules apply. Urethane paints cure from the bottom out, as opposed to lacquers which cure very quickly and from the top. When urethane paint cures, it skims the top layer to become dust free, and takes 30 to 90 days to fully cure in many cases. When a helicopter is painted, the operator should allow 90 days before polishing the paint with any products. There are many products to choose from in the detailing world. I suggest not using petroleum-based, silicon-based or wax-based products.

A good spray detailer is ideal for daily cleaning. Avoid washing the helicopter in direct sunlight. It’s best to wash the helicopter in the early morning or in the shade if a hangar is not available. At the end of the day, washing the aircraft before it has a chance to cool down from flight operations could pose a problem for the paint, especially if parts of the helicopters fuselage are hotter than 150 degrees, depending on the color of the paint. Water and cleaner hitting that surface can shock the finish and cause premature cracking and fading. Do not use Ajax dish washing detergent, Palmolive hand cleaner or similar products while washing the ship. Many mechanics think that “soap is soap” but that is not the case. Most auto supply stores carry an approved soap, where one ounce of product mixed with three gallons of water is fine. These types of cleaners will clean, protect and enhance the paint finish.

After the initial 90-day cure time has passed, it’s time to polish the helicopter. It’s good practice to apply a polish every 90 days thereafter. Do not use wax or wax products of any type. Wax will dull the finish and cause premature paint failure. Wax will prevent your paint from breathing. When you trap the solvents in with wax, they are forced to go another direction. This usually causes peeling, crazing and flattening of a finish. Using clean micro fiber towels for detailing, washing and polishing is the safest route. All these products are safe for Lexan, Plexiglas, metal and paint surfaces.

Simple Field Repairs of Paint

Most A&P mechanics with the basic grasp of the paint system used can performing paint repairs in the field.

Step 1. Determine the type of product used i.e., DuPont Aviation Finishes, Imron, Sherwin Williams, etc.

Step 2. Identify the material needing touch up. Is it a composite, aluminum or stainless steel?

Step 3. Check the maintenance manual for procedures on the particular panel to be painted. Many panels can be a composite where an anti-static primer is needed. Examples are magnesium or aluminum panels where special pretreatments are required. Stainless-steel panels also need a special etch primer. Obtain all the necessary materials to perform the job once you identify what they are.

For this example, we will use a general panel for the procedures.

Step 1. Clean the entire area with a wax and grease remover first. Many mechanics make the mistake of starting to sand first. By doing this, the wax and oil will actually get sanded deep into the surface and cause fish eyes and peeling.

Step 2. Once the entire area is cleaned, mask the area for refinishing by using a quality masking tape. If repainting a stripe area, use blue fine-line vinyl tape to get a crisp paint edge. Repair the area as necessary and prep, using alodine if required.

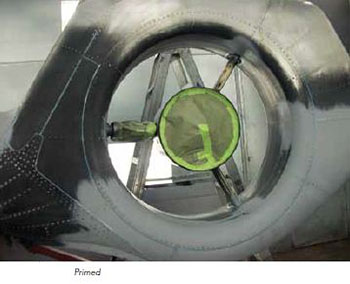

Step 3. Next apply the appropriate primer. Most primers used today have a “top coat” window. What that means is that once you apply the primer, you must wait the recommended amount of time (but not longer than the time specified) before applying the top coat. A common time frame is two hours but no longer than 24 hours. By doing this, you guarantee a chemical bond where the primer and paint adhere chemically. This is the strongest and most desirable bond. If too much time has elapsed, you will have to achieve a mechanical bond.

Step 4. Lightly sand the surface with 400-grit sandpaper prior to the topcoat application. Wipe away all dust with a tack cloth. Mix the paint in accordance with the manufacturer’s specifications. Don’t deviate from the directions. Many times mechanics like to stray away from the directions because they “know better.” The manufacturer will tell you how many coats to apply and what pressure and mix ratios to use. They will specify the time in between coats.

Follow these simple guidelines and you can keep all of your helicopter’s panels looking like they just came from the factory.

Stephen Jackowski is president of Advanced Aircraft Maintenance which is located at the Allegheny County Airport in West Mifflin, Pa. Jackowski has 25 years of painting experience and is a certified A&P and IA mechanic and inspector. Advanced Aircraft Maintenance is a DuPont-certified paint facility providing refinish work for some of the largest rotorcraft operations in the nation.

Stephen Jackowski is president of Advanced Aircraft Maintenance which is located at the Allegheny County Airport in West Mifflin, Pa. Jackowski has 25 years of painting experience and is a certified A&P and IA mechanic and inspector. Advanced Aircraft Maintenance is a DuPont-certified paint facility providing refinish work for some of the largest rotorcraft operations in the nation.