Power, Power, Power

When designing a helicopter, whether a light, intermediate, medium or heavy-lift platform, nothing flies without power. The helicopter OEM always wants the most power from the smallest and lightest engine possible. Likewise, engine OEMs will design an engine to be used in a single or dual configuration that is designed for a particular weight class helicopter. Turbomeca, a leading helicopter engine manufacturer, has developed the Ardiden 3, a new turboshaft engine with a completely different design concept. The Ardiden 3 is based on the same architecture as the Ardiden 1H1 engine.

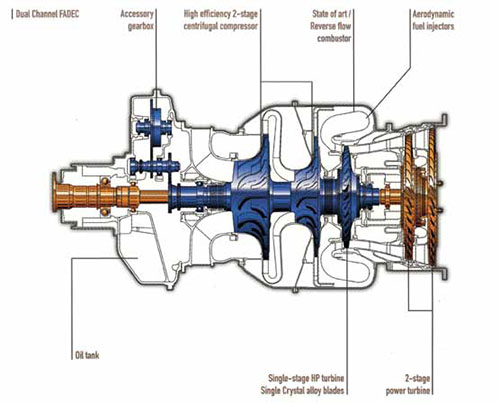

It is built around a gas generator with two centrifugal compressor stages coupled to a single-stage, high-pressure turbine. The power turbine comprises two stages. The engine is controlled by a dual-channel engine electronic control unit (EECU). With its simple and modular design, the Ardiden 3 offers low-cost maintenance and ownership. It is designed to develop a power from 1,700 to 2,000 shp and is dedicated to the six- to eight-ton helicopter market, providing a 200nm range. It has already been selected by China and Russia to power the AC352 and Ka-62 helicopters, respectively.

With a modular design and two-channel full authority digital engine control (FADEC), Ardiden 3 engines have high reliability, low operational costs (time between overhaul is 5,000 hours as of the date of the engine’s entry into service, and then more than 6,000 hours), and a low fuel consumption rate (about 10 percent less than other engines with similar output).

The following interview was conducted with Turbomeca in France.

HeliMx– What was the driving force behind the development of the Ardiden 3 engine?

Turbomeca– With the outstanding growth of the medium-heavy helicopter market segment, Turbomeca understood the need operators have for a modern engine exhibiting high-level power along with significantly lower fuel consumption, low direct maintenance costs through easy maintenance, and world-class reliability. Turbomecas’ answer to this market need is the Ardiden 3 engine family with 10-percent improved fuel consumption versus current engine market offerings, an easy-maintenance concept and high reliability at entry into service.

HeliMx– How was the name for this engine chosen?

Turbomeca– Following Turbomeca’s tradition, the engines have names of peaks, lakes or traditions of the Pyrenees, the region in which Turbomeca has its headquarters. Ardiden is the name of a peak and of a group of seven lakes in the Pyrenees.

HeliMx– Is there a particular reason for basing the engine on the Ardiden 1’s architecture?

Turbomeca– Yes, based on Ardiden 1 architecture, Ardiden 3 embeds proven technological bricks such as dual FADEC for increased safety, dual centrifugal compressor for high rotor acceleration rate, reverse-flow annular combustor chamber for low emissions, uncooled high-pressure turbine and power turbine for better fuel consumption. The result is this proven performance Ardiden 3 engine for six- to eight-ton helicopters.

HeliMx– Is it still a modular concept engine?

Turbomeca– The Ardiden 3 family of engines again exhibits a modular concept for easier operational maintenance activities, i.e., FADEC, accessory gear box, engine core and power turbine.

HeliMx– From a maintenance perspective, what has remained the same as its predecessor and what has changed?

Turbomeca– As Arriel, Arrius and Makila engine families, the Ardiden 3 modular concept allows operators high flexibility in their maintenance. Specific focus was set on the optimization of preventive maintenance for enhanced aircraft availability, components accessibility and extensive borescope inspection capabilities for easier and more accurate diagnosis. Ardiden 3 design is deep-maintenance friendly, thus limiting returns to the repair shop and increasing operational availability. Operator’s logistics were further simplified by allowing each engine to be installable on both the left and right sides without configuration change.

HeliMx– What is the engine’s TBO and MTBF?

Turbomeca – The engine’s TBO will eventually reach 6,400 hours. No MTBF figure can be given since entry into service is not until 2014. Based on the return of Turbomeca’s engines in service and Ardiden 3’s high level process of qualification, the MTBF of the Ardiden 3 is expected to be outstanding.

HeliMx– Does the cycle of preventative maintenance change from other Turbomeca engines in the same class?

Turbomeca– To sustain high operational availability, as for all recent Turbomeca engines, preventive maintenance is made consistent with helicopter OEM maintenance.

HeliMx– Are there any major differences in how maintenance should be performed on this engine, compared to its predecessor?

Turbomeca– The Ardiden 3 design embeds Bank of Online Service and Technology (BOOST) capability, Turbomeca’s range of online services to streamline operations. BOOST, part of a major Safran group project, answers essential helicopter operator needs, addressing aircraft safety, increasing operational availability and optimizing maintenance and operations costs. BOOST offers operators more visibility and expertise to get the most out of their engines.

Thanks to BOOST, a highly-secured and compatible platform developed in association with IBM, Turbomeca’s current engine support services will broaden and develop into real proactive actions and practices.

Through BOOST, Turbomeca operators will have access to services such as electronic engine logbooks linked to Web-based interactive technical publications to manage their maintenance and configuration. BOOST will propose services in an added value modular and flexible offer to

• Smooth and facilitate operations and airworthiness tasks

• Help in maintenance activities and planning

• Provide tools for expertise and analysis of engine trends

• Facilitate fleet and configuration management.

Turbomeca will start offering services towards the beginning of 2014. The new Turbomeca Ardiden 3 is ready for takeoff.