ARRIEL 2D - THE NEW STANDARD FROM TURBOMECA

If you are a helicopter A&P mechanic, there is an outstanding possibility that either now or somewhere during your career, you have worked or will work on a Turbomeca engine. For those of you that have not, Turbomeca is part of the Safran group. Safran is an international high-technology group with three core businesses: aerospace, defense and security. Operating worldwide, the group has nearly 60,000 employees. Turbomeca specializes in the design, production, sale and support of low- to medium-power gas turbine engines for aircraft. Including its joint programs with other manufacturers, Turbomeca today is the world’s leading provider of helicopter engines.

With more than 75 years of experience, logging more than 88 million hours of engine operating time and boasting more than 2,300 customers in 155 countries, it’s worth a look when Turbomeca introduces a new engine.

An Overview

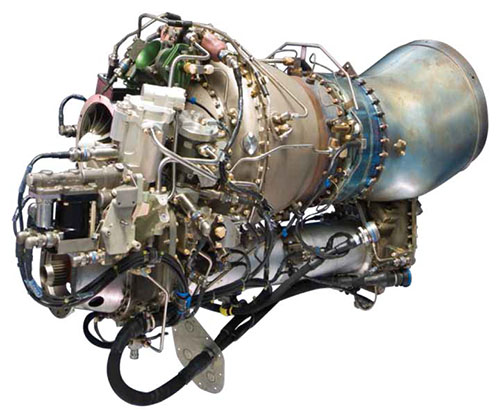

The Arriel 2D is a continuation of the evolution of the Arriel family of engines. The Arriel family started with the certification of the Arriel 1B in 1977 with 640shp. In 1988, the Arriel 1D1 was certified with 731shp. The Arriel 2B1 came along with 846shp in 2000 and in 2011 the Arriel 2D was certified with 951shp. In total, the Arriel fleet encompasses more than 10,000 engines delivered, with more than 35 million flight hours. They are found on more than 60 percent of all helicopters worldwide in the 700-900shp power class.

The Arriel 2D is designed for light, single-engine helicopters in the 5,000-pound weight class. It’s currently on the AS-350B3 and EC-130T2 helicopters.

It’s still a modular design engine that has found great acceptance from the maintenance community. From the maintenance perspective, some things have changed and some have not. The entry into service is based on proven Arriel maintenance practices requiring little additional training. The scheduled maintenance tasks are basically the same, just at different intervals. The new systems like the engine data recorder (EDR), the creep counter and the engine monitoring program will better help project and schedule maintenance tasks.

So What’s New?

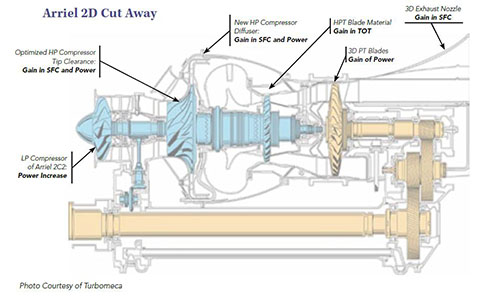

Technical improvements include a new axial compressor, new HP compressor diffuser, and new HP turbine blade material. Performance is enhanced with a new rating and limitation, increased time between overhaul (TBO) and increased time between inspections. These changes help reduce the overall direct operating costs.

The Arriel 2D has a new generation dual-channel full authority digital engine control (FADEC) that provides engine state monitoring (fuel and oil filter clogging.) It also boasts engine regulation NG and T45 for better power optimization and mean time between unscheduled removal (MTBUR) improvement. The TBO for entry into service is 4,000 hours, but the mature target is 6,000 hours. That’s a 50-percent increase.

Fuel consumption, when compared to the Arriel 2B1, is projected to be two percent less. This translates into lower operating costs and increased range. The Arriel 2D also has a greater electrical power output available.

Optimizing Reliability

Engine trend monitoring allows for better detection of engine wear and tear at an earlier point in time. This, in turn, allows appropriate corrective action to take place before safe operation is affected.

The EDR is the data memory for the engine. It holds all of the conformation data. It also records engine data/parameters with a possible download to a ground station, and then to a centralized database for access to services. EDR advantages include easier FADEC replacement and larger storage capacity compared to the FADEC, as well as the fact that the engine becomes natively compatible with future integrated electronic services for line maintenance support. These services, coupled to the EDR, will allow for reduced operating costs, improved engine availability and improved productivity for the operators.

The creep counter measures real time creep deterioration of the HP blades. This allows the operator to anticipate required maintenance actions, reduce unscheduled removals and thus optimize helicopter availability and know engine aging independent of the TBO.

Advanced Technology

The first electronic tools are already available. The interactive electronic technical publications (IETP) is becoming available. Troubleshooting software will be in the ITEP through an interactive “fault tree” format that will include direct links to the maintenance manual.

Training for the Arriel 2D engine began in July 2011. Turbomeca USA is working with Eurocopter to align training courses to coincide with airframe courses. Operators that are currently certified on Arriel 2B/2B1 engines will only require a one-day “engine differences” course.

Specific tooling for the Arriel 2D engine is limited. Most of the tooling used on the Arriel 2B1 engine can be used. At entry into service, repair and overhaul capability will be at the Turbomeca Tarnos, France facility. Turbomeca USA will be qualified for repair this year.

Specific customer support plans can be tailored to meet specific customer requirements. Designed to stabilize and reduce overall engine operating costs, these plans can allow for fleet monitoring by the operator or maintenance provider and offer program management assistance.

The Arriel 2D is the latest and greatest turbine engine from Turbomeca for the 5,000-pound class helicopter. With its new features and proven modular design, it looks like it’s ready to take its place in the Arriel family of engines.